Cold plunge pools maintenance presents a unique challenge in the pool industry due to their relatively recent introduction and the specific requirements of lower water temperatures. Unlike traditional swimming pools and hot tubs, cold plunge pools require specialized knowledge and techniques to ensure they remain clean, safe, and functional. This article demystifies the intricacies of cold plunge pool maintenance, offering essential tips and best practices tailored for Pool Service Professionals. By understanding the nuances of water chemistry, filtration, and equipment maintenance specific to cold plunge pools, Pool Service Professionals can ensure these innovative wellness features are maintained to the highest standards.

Let’s uncover the secrets of effectively managing cold plunge pools together and elevate your expertise in this emerging industry.

Photo by Lukas Kubica on Unsplash

Cold water samples and test chemicals

Water Chemistry Management involves monitoring key parameters: pH levels (ideal range 7.2-7.8), total alkalinity (80-120 ppm), calcium hardness (200-400 ppm), free chlorine (1.0-3.0 ppm), and total dissolved solids (TDS) (<1500 ppm). Colder water temperatures stabilize pH levels but slow down chemical reactions, making frequent monitoring essential. Total alkalinity in cold water can be affected by slower chemical reactions, necessitating closer attention to buffering capacity to prevent sudden pH changes. Maintaining calcium hardness is crucial to prevent scaling, which is more likely in cold water due to the lower solubility of calcium compounds. Chlorine’s effectiveness decreases in cold water, requiring regular adjustments to ensure proper sanitation. High TDS levels, which reduce sanitizer effectiveness and cloud the water, should also be regularly checked.

Chemical Adjustments for balancing pH include adding sodium carbonate (soda ash) to raise pH or muriatic acid to lower it, with gradual adjustments to avoid overcorrection. Adjusting alkalinity involves adding sodium bicarbonate for low levels and muriatic acid for high levels, ensuring chemicals are well-mixed to counter the slow dissolution rates in cold water. For calcium hardness, adding calcium chloride helps with low levels, while high levels may require partial drainage and refilling of the pool. Regular chlorine maintenance involves keeping free chlorine levels between 1.0-3.0 ppm, with periodic shock treatments to break down chloramines, particularly important in cold water where chlorine’s effectiveness is reduced.

Aggressive vs Scale Forming

The Langelier Saturation Index (LSI) is essential in maintaining a cold plunge pool. The LSI is a calculated number used to predict the calcium carbonate stability of water, which helps determine whether the water will precipitate, dissolve, or be in equilibrium with calcium carbonate.

Practical Steps for Maintaining LSI in Cold Plunge Pools

- Regular Testing: Regularly test the pool water for pH, total alkalinity, calcium hardness, and temperature to calculate the LSI. Use reliable test kits to ensure samples are accurately taken at room temperature.

- Chemical Adjustments: Make necessary pH, alkalinity, and calcium hardness adjustments based on LSI calculations. Use sodium carbonate or muriatic acid to adjust pH, sodium bicarbonate for alkalinity, and calcium chloride for calcium hardness.

- Monitoring Temperature: Keep an eye on water temperature changes, especially in outdoor cold plunge pools, as temperature significantly impacts the LSI. Adjust chemical parameters accordingly to maintain a balanced LSI.

Photo by Mika Ruusunen on Unsplash

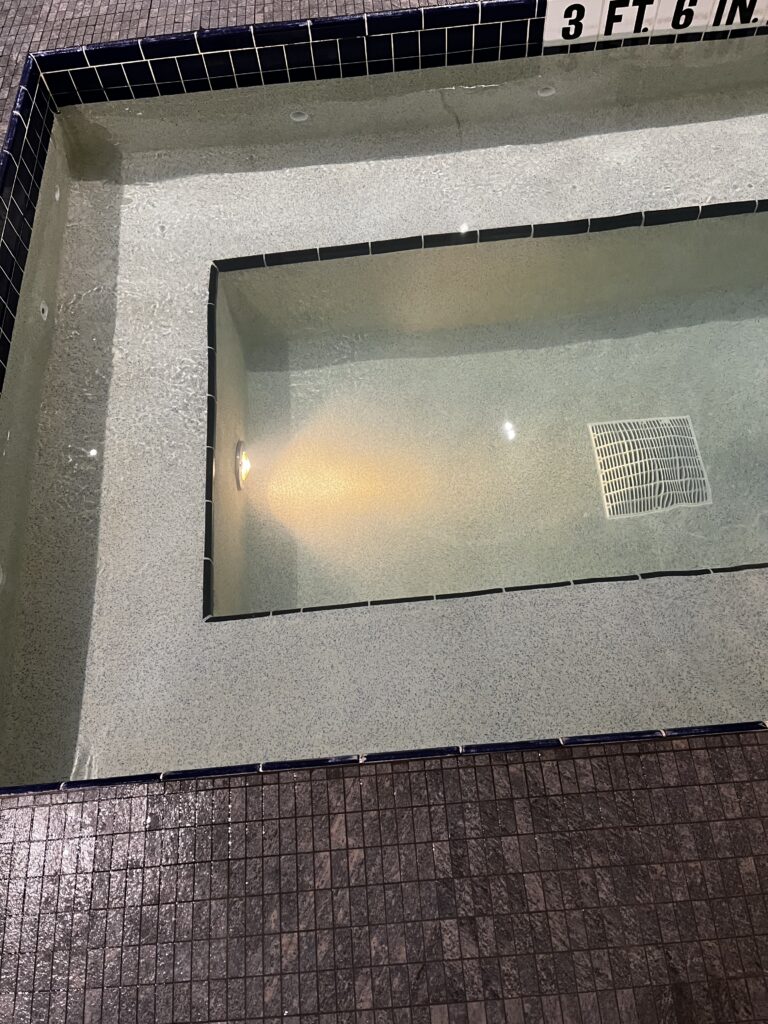

Specialty Chemicals such as enzymes, phosphate removers, and stain preventatives play a vital role in maintaining water quality. Enzymes break down organic matter but may work more slowly in cold water, necessitating weekly additions. Phosphate removers help prevent algae growth even in cold conditions, applied based on test results. Yes!!! Algae can grow in 50F water… Stain preventatives, used regularly, prevent metal stains and scaling, which are more likely in cold water environments.

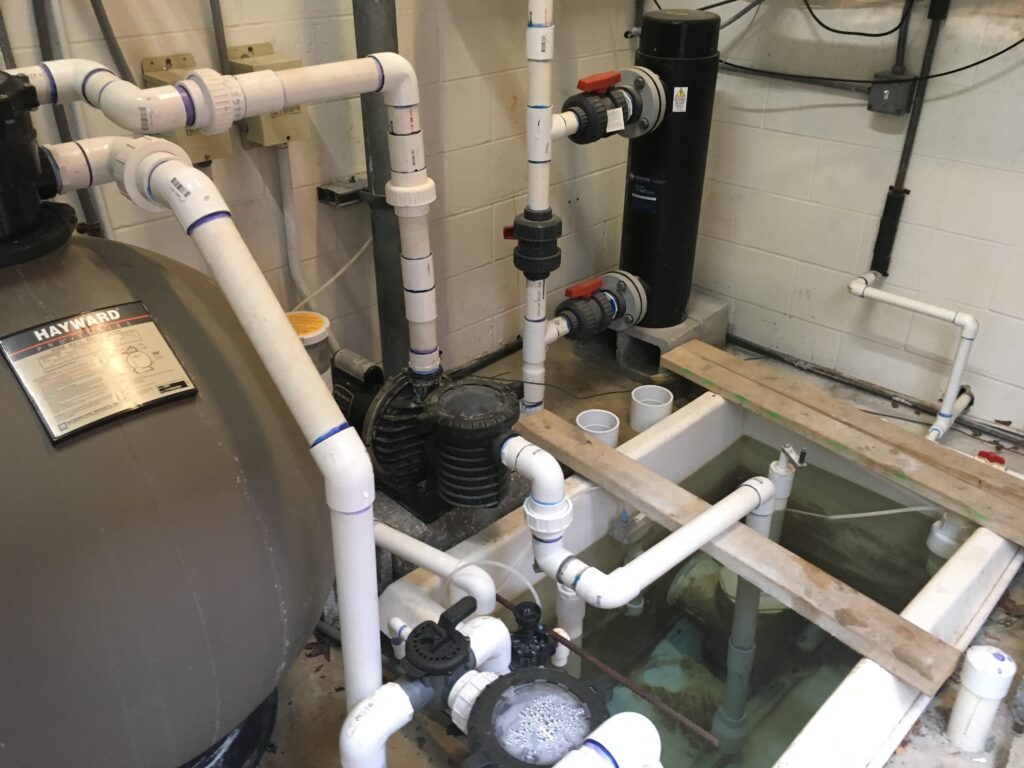

The Euipment is sweating!

Mechanical maintenance includes regular inspection and cleaning of pumps, motors, filters, and chillers. Pumps and motors should be checked for wear and lubrication needs, as cold temperatures can cause seals and gaskets to harden. Filters need bi-weekly cleaning or backwashing, with media replaced according to manufacturer recommendations. Chillers, under constant strain to maintain low temperatures, require clean condenser coils, proper refrigerant levels, and regular inspections for leaks and efficiency. Proper water circulation is essential to prevent cold spots and ensure even chemical distribution.

Condensation forming on the filter on a cold plunge witha water temp of 50F on a 90F day

Deep Cleaning and Sanitization involve routine skimming and debris removal at least twice a week, with bi-weekly scrubbing of pool surfaces to prevent biofilm formation. UV or ozone generators, if used, should have their quartz sleeves cleaned and UV lamps or ozone cells replaced as per the manufacturer’s schedule to supplement chemical sanitization in cold water. Winterizing the pool includes draining, cleaning, drying components, and proper storage to prevent freeze damage.

Do women know about shrinkage?

Jerry Seinfeld, ‘The Hamptons’ TV episode, 1994

Health and Safety measures are crucial in preventing diseases such as Legionnaires’ disease, caused by Legionella bacteria. Maintaining recommended chlorine levels and controlling biofilm formation through regular cleaning helps mitigate this risk. Monitoring water temperature prevents hypothermia, and maintaining balanced chemical levels prevents skin irritation, which can be exacerbated by cold water.

A Few More Tips

Encouraging users to shower before entering the pool can significantly reduce the amount of organic matter and contaminants introduced into the water, helping to maintain water quality and reduce the load on filtration and chemical treatment systems. Additionally, installing foot cleaning stations or rinse areas near the pool entry can help prevent dirt and debris from being brought into the pool.

Ensuring the pool’s circulation system is designed to provide adequate water turnover is crucial, as cold plunge pools often require more frequent water turnover due to their smaller volume and higher contaminant load from users. Proper hydraulic design can prevent dead zones where water circulation is insufficient, which can lead to localized areas of poor water quality.

Cold Plunge Pool pump room at a commercial facility

The recommended turnover rate for a cold plunge pool is typically between 30 minutes to 1 hour. This means the entire volume of water in the pool should be filtered and circulated within this timeframe to maintain optimal water quality and hygiene. Factors influencing turnover rate include pool size and volume, bather load, and water temperature. Smaller pools require a higher turnover rate due to their limited water volume and higher user-to-water ratio. Higher usage demands more frequent turnover to handle the increased introduction of contaminants and organic matter. Colder water slows down chemical reactions and can reduce the efficacy of sanitizers, necessitating more frequent circulation to ensure proper chemical distribution and filtration.

General guidelines for turnover rates suggest that maintaining a turnover rate closer to 30 minutes is advisable for commercial settings, where usage is typically higher. This ensures that the water remains clean and free from contaminants despite heavy use. For residential pools with lower usage, a turnover rate of up to 1 hour may be sufficient. However, if usage increases or if the pool is exposed to environmental contaminants, this rate should be adjusted accordingly.

Rapid Turnover Rates

Additional considerations include ensuring the pool’s filtration system is capable of handling the required turnover rate without being overburdened. This includes proper sizing of pumps, filters, and any auxiliary equipment like UV or ozone systems. Regular filtration system maintenance, including cleaning and replacing filters, is crucial to maintaining the desired turnover rate and overall water quality. Always check local health and safety regulations, as they may have specific requirements for turnover rates, particularly for commercial or public cold plunge pools.

Consider using secondary filtration systems such as diatomaceous earth (DE) filters or cartridge filters in addition to the primary sand filters. These can capture finer particles and improve overall water clarity. UV and ozone systems provide additional disinfection and help reduce reliance on chemical sanitizers, being particularly effective in colder water where chlorine is less effective.

Regularly calibrating testing equipment such as pH meters and ORP sensors is crucial, as even slight inaccuracies can lead to improper chemical dosing. Ensuring that flow meters and thermometers are calibrated and functioning correctly is also important to monitor water flow and temperature accurately.

For outdoor cold plunge pools, consider the impact of environmental factors such as rain, wind, and foliage, and use covers to protect the pool from debris and contaminants. For indoor pools, ensure proper ventilation and humidity control to prevent condensation and mold growth, which can be exacerbated by the temperature differences between the cold pool water and the warmer surrounding air.

Keeping detailed records of all maintenance activities, chemical additions, and water testing results helps track the pool’s condition over time and identify any recurring issues. Adhering to all manufacturer guidelines for equipment maintenance and chemical usage ensures warranties remain valid and equipment operates efficiently.

Providing clear instructions and guidelines for pool use, including the maximum recommended duration of immersion to prevent hypothermia, is essential. Installing safety signage around the pool area to inform users of the cold plunge pool’s unique conditions and any precautions they should take enhances user safety.

By incorporating these additional considerations into your maintenance routine, you can further ensure the cleanliness, safety, and efficiency of cold plunge pools, providing a better experience for users and prolonging the life of the pool and its equipment.

References:

- CDC – Legionella (Legionnaires’ Disease and Pontiac Fever): CDC Legionella

- WHO – Legionella and the prevention of legionellosis: WHO Legionella

- Plunge Blog: How to Keep Your Cold Plunge Clean

- Recovatech: How to Keep Your Cold Plunge Clean: Essential Sanitation Tips

- Cold Plunge Culture: Maintenance Made Easy: Simple Techniques for Keeping Your Cold Plunge Water Impeccably Clean