If you’re a pool plasterer, you’re no stranger to the challenges posed by concrete in wet environments. But there’s a hidden threat looming beneath the surface of swimming pools across the country—concrete cancer, also known as alkali-silica reactivity (ASR). This destructive force can erode the structural integrity of pools, leading to costly repairs, reputation damage, and in severe cases, complete rebuilds. Understanding ASR and how to prevent it is critical for pool builders and plasterers alike.

Listen to the episode on concrete cancer here

What Is Concrete Cancer?

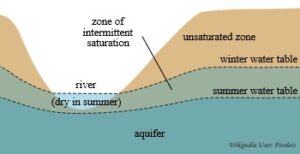

Concrete cancer, specifically ASR, refers to the chemical reaction between alkali hydroxides in cement and reactive silica found in some aggregates. This reaction produces a gel-like substance that expands when exposed to moisture. In a constantly wet environment like a swimming pool, this gel expansion exerts enormous pressure on the surrounding concrete, leading to cracking, spalling, and the deterioration of the structure. Over time, this weakens the concrete, jeopardizing the entire integrity of the pool.

Rudy Stankowitz, a well-known figure in the pool industry, explains that ASR is a significant problem not just for pool builders but also for service professionals who often face the fallout of poor construction practices. ASR has been wreaking havoc, particularly in places like Central Texas, where a combination of reactive local aggregates and shortages of materials like fly ash have exacerbated the issue. Pools built between 2017 and 2023, during a boom in construction and the COVID-19 supply chain crisis, are now showing alarming signs of ASR

Why Should Pool Plasterers Be Concerned?

For plasterers, the health of the pool’s concrete foundation is paramount. ASR can undo your work faster than you can imagine. A client may blame the plaster for problems when the root cause is the underlying concrete cancer eating away at the structure. If unnoticed or ignored, ASR can destroy a pool beyond repair, leading to lawsuits, financial losses, and tarnished reputations for builders and plasterers alike.

Identifying the Signs of Concrete Cancer

As a pool plasterer, it’s important to be vigilant in identifying the early warning signs of concrete cancer. The most obvious signs include:

- Cracks: These may appear small at first but can spread rapidly as the ASR reaction progresses.

- Spalling: Chunks of concrete flaking or breaking off.

- Rust Stains: This is a result of corroded rebar that has expanded and compromised the concrete.

- White Gel-Like Substance: This indicates that the ASR reaction is underway and moisture has begun to seep into the concrete.

similar article Plaster, Fiberglass, & Vinyl Pool Surface Fails

If you see these signs, it’s critical to alert the pool builder and the client. Early detection can sometimes prevent further damage, but the only surefire way to stop ASR once it’s started is a complete demolition and rebuild of the pool.

Preventing Concrete Cancer: What You Can Do

The best way to fight ASR is to prevent it from happening in the first place. For pool plasterers, this means demanding high-quality materials and staying informed about best practices in pool construction.

- Use Low-Alkali Cement: One of the most effective ways to reduce the risk of ASR is to use low-alkali cement in the concrete mix. This minimizes the alkali content, which reduces the chances of the alkali-silica reaction occurring.

- Select Non-Reactive Aggregates: Ensure that the aggregate used in the concrete mix is non-reactive. Aggregates containing reactive silica are the primary culprits in ASR, and by avoiding them, you can greatly reduce the risk.

- Incorporate Supplementary Cementitious Materials (SCMs): SCMs, such as fly ash, slag, and silica fume, help lower the overall alkalinity of the concrete. These materials not only mitigate ASR but also enhance the strength and durability of the concrete. As Rudy noted, the lack of fly ash during the COVID supply chain disruptions contributed significantly to the rise in ASR-related failures

- Ensure Proper Waterproofing: Pool plasterers play a key role in ensuring that the concrete is properly waterproofed. Apply waterproof coatings and sealants to create a barrier between the water and the concrete. This can prevent moisture from penetrating the surface and reaching the rebar, which is the primary cause of corrosion and concrete cancer.

Addressing Existing ASR Damage

If ASR is already present, immediate action is crucial to prevent further damage. Depending on the severity, different methods may be employed:

- Localized Repairs: For minor damage, cutting out the affected section and replacing it with non-reactive materials can help prevent future issues. The new concrete should be made with low-alkali cement and non-reactive aggregates.

- Crack Injection: For cracks caused by ASR, injecting epoxy or polyurethane can seal the cracks and restore the structural integrity of the concrete.

- Protective Coatings: Applying protective epoxy or polyurethane coatings to the entire pool surface can provide a waterproof barrier, extending the pool’s life by preventing future ASR-related damage.

similar article Tight Spaces and Spaghetti Bowl Pads | AQUA Magazine

The Financial and Reputational Toll

In places like Central Texas, the fallout from ASR has been devastating for both homeowners and pool companies. Pools built during the 2017-2023 boom are showing significant damage, leading to lawsuits, bankruptcies, and damaged reputations for builders and plasterers. Entire pools are being demolished and rebuilt due to the severity of the ASR damage. It’s a stark reminder of how vital material selection and construction practices are in avoiding these catastrophic failures.

Conclusion

As a pool plasterer, your role goes far beyond the surface layer. Understanding the underlying structure and the potential risks like ASR can help you safeguard not only the pools you work on but also your professional reputation. By staying informed about concrete cancer and advocating for high-quality construction materials and methods, you can ensure that your clients’ pools stand the test of time. Remember, preventing ASR starts at the foundation, and with the right precautions, you can avoid the financial and emotional toll that comes with this destructive process.

If you ever have questions or need more information about preventing concrete cancer, feel free to reach out. Together, we can help build pools that last a lifetime.