This is probably a bit overdue, but we decided it would be easiest to bullet point the CyA removal method we are field testing. So, here is the Alum CyA Removal Method (Still in the test phase). I have partnered with John Poma on the list of steps in this write up as he has conducted more field applications of this method than any other pool professional I am aware of. Here is the step-by-step process.

Similar Article Lower Cyanuric Acid in Swimming Pools Chemically

[responsivevoice_button voice=”UK English Male” buttontext=”Listen to Post”]

Alum CyA Removal Method.

- Adjust pH to 7.0 (Critical)

- Adjust Total Alkalinity to 80 to 120 ppm, Calcium Hardness to 200 – 400 ppm, Water Temperature to 70℉ to 90℉ (Critical)

- Ensure the pool is free of heavy debris that could stir the ‘Floc’ upon vacuum to waste.

- Test Cyanuric Acid Level.

- Filter Preparation

- Sand & DE Filters: With the pump off, manipulate the multiport valve to ‘Recirculate’ position.

- Cartridge Filters: With the pump off, remove the filter element and then reassemble without it.

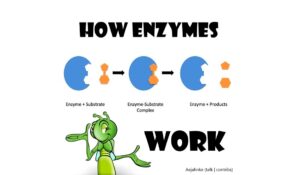

- Broadcast Aluminum Sulfate at a rate of 8.33 lbs per 10,000 gallons of water.

- Set time clock to run the pump for two hours and then shut off.

- Remove the ‘ON’ tripper from the time clock to avoid unintentional circulation.

- Allow the pump to remain off for a minimum of 12 hours. Do NOT allow the pump to run again until the entire process is complete and elements replaced with valves in the correct run positions.

- With a PORTABLE VACUUM SYSTEM, vacuum the floc to waste at a pace slow enough not to stir or ‘break’ the floc.

- Test residual aluminum level (should be < 0.2 ppm)

- Test Cyanuric Acid level.

- Post your results in the comments below.

NOTE: We are not recommending this method for saltwater pools and/or pools with pigmented plaster at this time – further testing is required.

DO NOT attempt the process above if you are not a Swimming Pool Professional.

Subscribe to Pool Operator Talk News

What was the pH? 7.3

What was the Total Alkalinity? 97

What was the Water temp? 70 f

Total hardness 113

Phosphates. 0

Free chlorine 0.01

Pool Gallons? 11887

Pounds of alum added? 5.5 lb

Cyanuric. 141

Copper. 0

Pool surface in rubber liner

System was running on recirculation for 5 hours and there was algae present in the pool

Reading taken once pool cyanuric level 130

Have you added within proximity of an algaecide? No

Type of CyA test kit used? Test strips and digital spin disc

Hello Shane, as far as the process goes it would make sense that you did not see a drop in CyA. The pH could be a hair lower, but that shouldn’t have caused a major issue. The dose was extremely light. For 11,887 gallons at the recommended dose of 8.33 lbs per 10K gallons, you should have added 9.90 lbs of aluminum sulfate. That’s a little shy of double the 5.5 lbs you had added.

After that, just for water balance sake, your calcium hardness level is low – some don’t believe this is a concern in vinyl liner pools, however, many manufacturers use calcium carbonate in vinyl construction – soft water has been shown to dissolve calcium from liners where production has utilized > 7% in the manufacturing process.

Hi Rudy second pool tested on as follows

Chlor 6, pH 6.9, alk 110, cal 200, CNA 160, temp 72f, phos 0, pool size 11887 gal, plaster marblesheen.

Alum added 13.22lb (we work in kg and LTRs excuse the exact number )

CNA level after vac to waste was 0 on test strips, from 6inches on water top.

95ppm on digital spin disc, this water was taken from over elbow deep.

CNA level 10 days after vac to waste 120ppm, my guess is that the 0 CNA reading after alum was added and vac, is the reading on the surface of water, also temp on surface of water 72f, Pool isn’t heated and returns might not be circulating the deep end as good as it should, maybe temp wasn’t enough??

I will try another pool next month as the weather is getting warmer and customers that don’t have heating in their pool, hopefully some smaller pools too.

Have a good Xmas and new year will keep you posted, cheers Shane