I’m afraid there’s not going to be anything pretty about this one. At least not with the diagrams. I want to talk about Why Pool Pump Cavitation Sucks and the pictures I want don’t exist. So, I apologize in advance. Hopefully, my drawings are not too horrible.

[responsivevoice_button voice=”UK English Male” buttontext=”Listen to Post”]

Why Pool Pump Cavitation Sucks!

For the most part, it’s easy enough to identify; the system starts to sound like there is gravel running through it, the flow rate fluctuates, and you may also have a steady stream of tiny bubbles coming back into the pool through the return jets. That’s not the mystery. It’s the reason a pump cavitates where the internet spews bull squat.

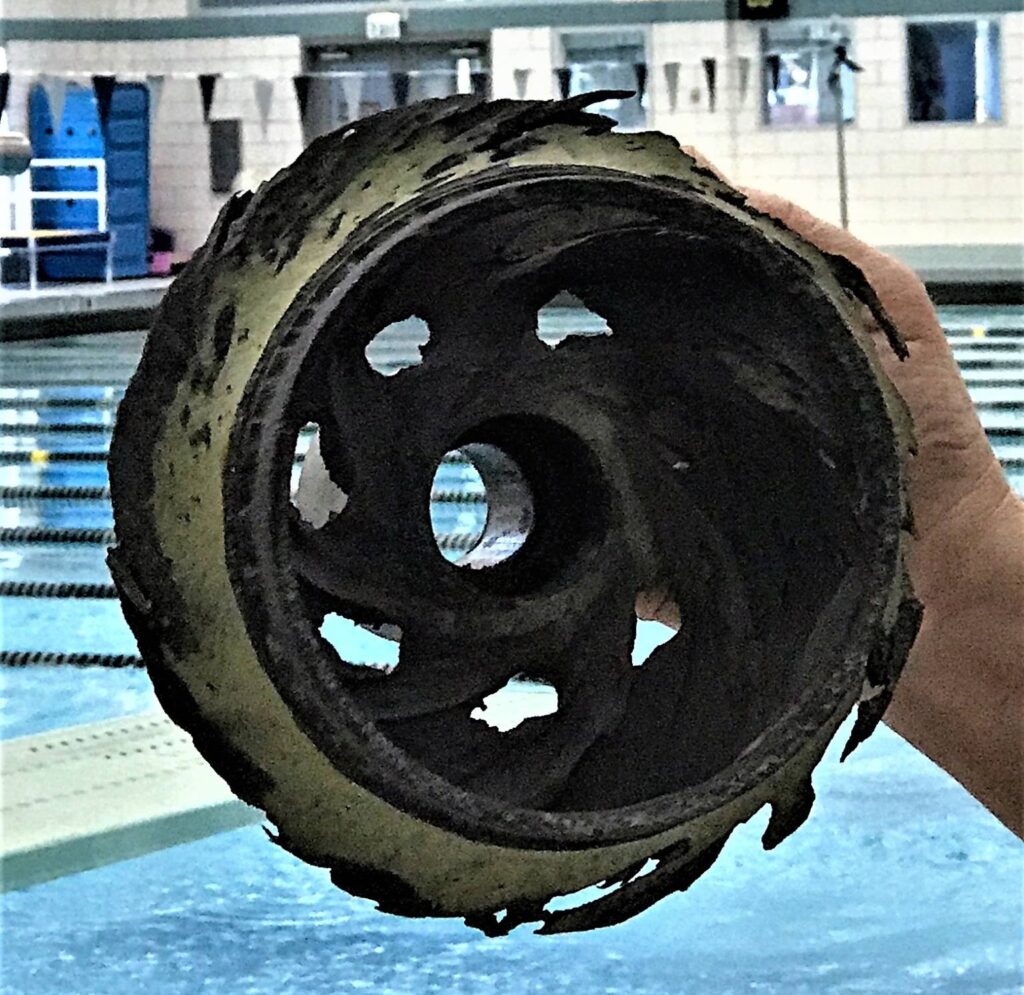

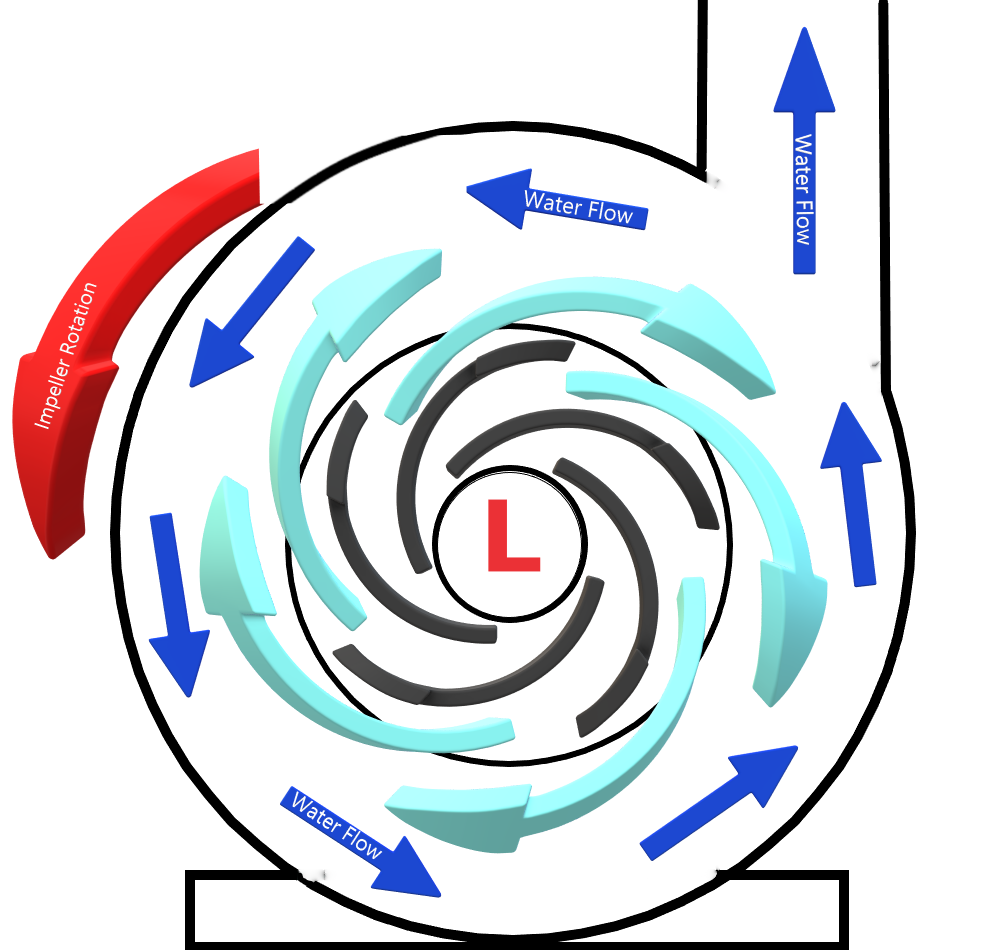

The impeller is the part of the pump that ‘throws’ the water. This is also the part of the system that takes the brunt of the damage when cavitation occurs.

The influent (inflowing) water is drawn into the wet end by the spinning impeller’s suction. After the water passes through the pump pot where the strainer basket is kept, it must enter the pump volute before it reaches the impeller. Or through a diffuser, if a diffuser pump is directed to the impeller’s eye.

.

.

Brass is 67% Copper and 33% Zinc

Bernoulli’s equation.

As the impeller spins (counterclockwise), centrifugal force exerts on the water. The rotation increases both its pressure and velocity, driving the liquid through the discharge and into the filter. This force creates low pressure at the eye, water from the pump pot rushes to fill, giving us the suction that draws the water from the pool.

Subscribe to our Pool Operator Talk eNewsletter

If something were to restrict the flow of water to the impeller, the pressure at the eye would drop further. This could be due to a full pump basket, incorrect valve position on the suction side, clogged suction pipe, stuffed skimmer basket, blocked main drain, or a vacuum filter (if present) in need of cleaning.

.

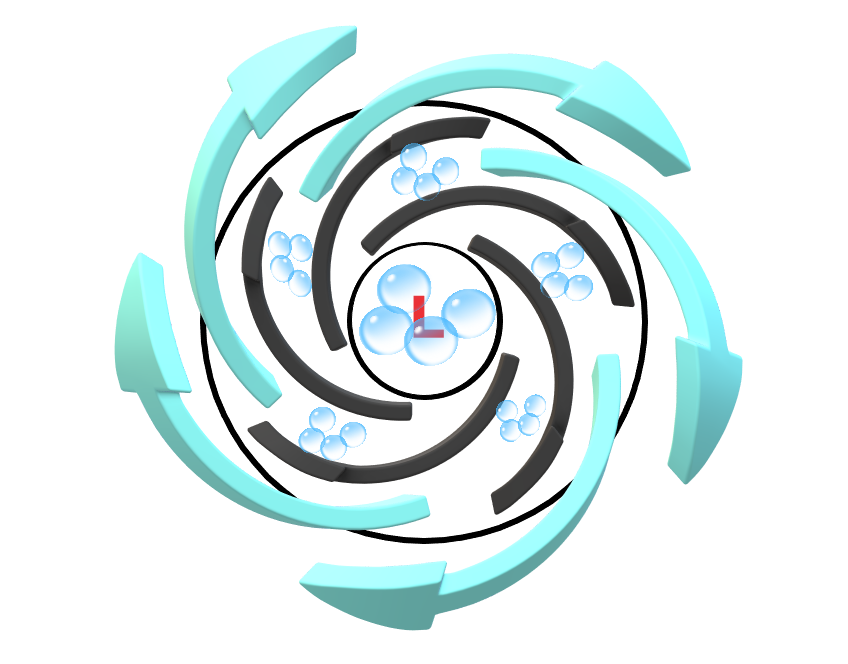

A low-pressure boil.

If the pressure drop were significant enough, the water would flash to steam. These steam bubbles are whisked along the veins of the impeller. Some get caught in the effluent (discharge) stream of water and may make it back to the pool. This explains the floor returns bubbles when a vacuum DE filter is long overdue for a cleaning.

.

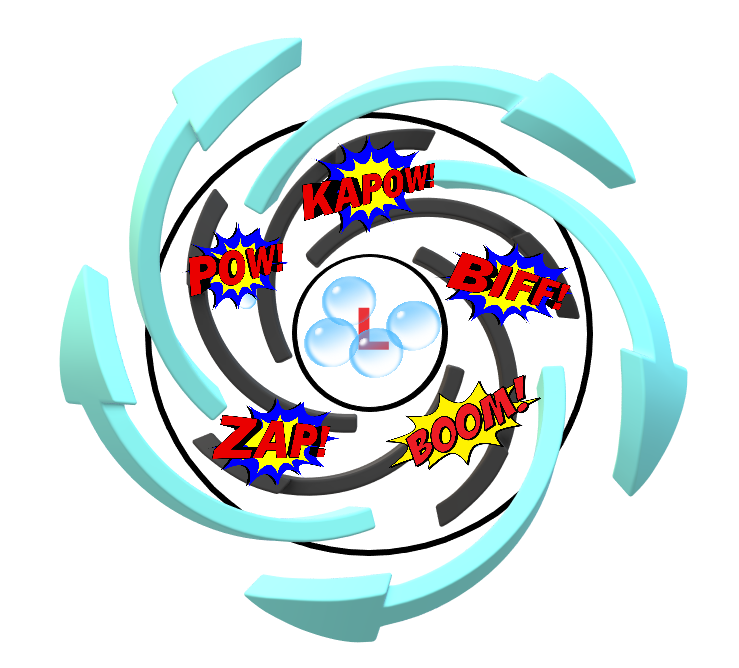

Collapsing of air bubbles.

Most of the bubbles won’t make it past the veins of the impeller. Once they reach the water with higher pressure, the bubbles begin to implode. The steam bubbles’ violent collapse sends shock waves through the water that can damage the pump’s internal components. This will cause pitting, and the impeller typically takes the bulk of the damage.

It is important to note that discharge cavitation also exists. When something, such as a closed valve, restricts the flow to the point it cannot easily leave the pump. Or if the flow is restricted downstream in the system (see video below).

When water trapped in the pump circulates within the wet end at a high velocity, it is forced through the narrow clearance between the impeller and the seal plate and the impeller and the volute, or diffuser if a diffuser pump. This will cause damage to the impeller, pump shaft, and other internal components when the steam bubbles collapse.

Check out our videos on YouTube

.

Can Cavitation Kill Algae & Bacteria?

This question comes up a lot. Can cavitation kill algae? The answer is, in many cases, yes. But this only applies to the organisms that come in contact with the shock waves from the bubble implosion. Then, consider the cost due to equipment damage and leaks caused by a continuous vibration through plumbing. That said, there is a lot of scientific literature available on cavitation for algae and bacteria control.

In everything I have read to date, the results have been pretty much in line with one another. A 90% eradication rate exists for most algae and bacteria, though kill time varies with species. Eradication rate is poor for some species, others see no effect, and at least one algae species growth rate increased. Not all studies look at both algae and bacteria – I attached the pdf for one that does below.

Mojca Zupanc, Žiga Pandur, Tadej Stepišnik Perdih, David Stopar, Martin Petkovšek, Matevž Dular,

Effects of cavitation on different microorganisms: The current understanding of the mechanisms taking place behind the phenomenon. A review and proposals for further research,

Ultrasonics Sonochemistry,

Volume 57,

2019,

Pages 147-165,

ISSN 1350-4177,

Abstract: A sudden decrease in pressure triggers the formation of vapour and gas bubbles inside a liquid medium (also called cavitation). This leads to many (key) engineering problems: material loss, noise, and vibration of hydraulic machinery. On the other hand, cavitation is a potentially useful phenomenon: the extreme conditions are increasingly used for a wide variety of applications such as surface cleaning, enhanced chemistry, and wastewater treatment (bacteria eradication and virus inactivation). Despite this significant progress, a large gap persists between the understanding of the mechanisms that contribute to the effects of cavitation and its application. Although engineers are already commercializing devices that employ cavitation, we are still not able to answer the fundamental question: What precisely are the mechanisms how bubbles can clean, disinfect, kill bacteria and enhance chemical activity? The present paper is a thorough review of the recent (from 2005 onward) work done in the fields of cavitation-assisted microorganism’s destruction and aims to serve as a foundation to build on in the next years.